A new report has been published!

Low Carbon Cement:

Harmonizing environmental goals and housing needs

By Anthony Boanada-Fuchs, Urs Heierli and Karen Scrivener

WHAT IS LC3 ?

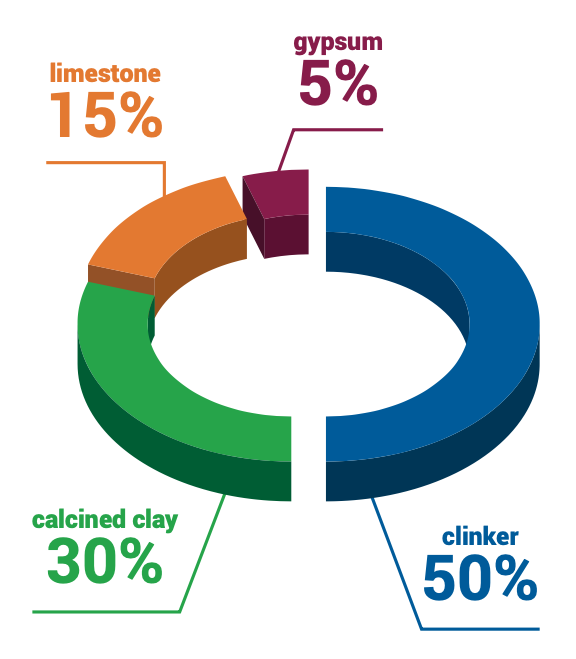

LC3 is a new type of cement that is based on a blend of limestone and calcined clay. LC3 can reduce CO2 emissions by up to 40%, is made using limestone and low-grade clays which are available in abundant quantities, is cost effective and does not require capital intensive modifications to existing cement plants.

The objective of the LC3-Project is, through research and testing, to make LC3 a standard and mainstream general-use cement in the global cement market.

The main research activities focus not only on specific thematic areas of cement research but also on production, environmental sustainability and cost effectiveness of this new cement.

With funding from the Swiss Agency for Development and Cooperation through its Global Programme in Climate Change, the has been able to bring the idea of the LC3-technology from the lab in Switzerland to all parts of the world.

LC3-Project status and activities around the world

Since 2014, the LC3-Project was supported by the Swiss Agency for Development and Cooperation (SDC). During the first three-year phase between 2014 and 2017, proving the technical feasibility of LC3 was the main goal. With the start of phase two in 2017, the focus shifted towards market preparation and implementing first productions and policy outreach. Hence, the LC3-Project’s activities included working on awareness creation (LC3-Information Days and conferences), building a support structure for the industry with the Resource Centres and conducting research on technical key question to facilitate the uptake of LC3.

Over the past three years, the outreach to cement producers has grown exponentially. At present, about 40 cement companies in 25 countries are interested in LC3.