- – A new report supported by the Swiss Agency for Development and Cooperation (SDC) suggests that low carbon cement could address climate goals and the global housing challenge, creating jobs and boosting the economy.

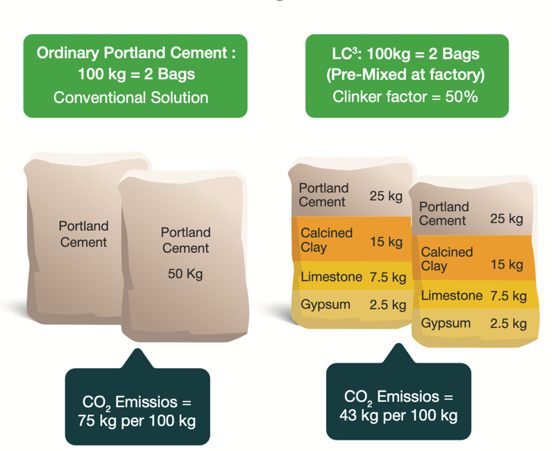

- – LC3, a low carbon cement formulation, paired with improvements in cement production and construction, can cut concrete-associated emissions by 70 percent.

- – Rapid adoption of LC3 in the Global South could preempt surging concrete demand triggered by demographic growth, economic development, and increased urbanization.

To meet sustainable development goals by 2030, about 600 million additional housing units need to be constructed compared to 2015 levels, primarily in Southeast Asia and Africa. A team led by Karen Scrivener, who heads EPFL’s Laboratory of Construction Materials, set out to assess the potential of LC3, a low carbon cement formulation, to meet this demand without the climate impact associated with concrete construction. They published their findings in a report that challenges common misconceptions about concrete and highlights its role in economic development across the Global South.

Addressing common misconceptions

“Many people, even architects, are biased against concrete in favor of wood, bamboo, or clay,” says co-author Urs Heierli. “But these materials don’t meet the needs of the Global South.” Why? Substituting a quarter of the 6.4 billion cubic meters of concrete used yearly with wood would require increasing global forest cover by 14 percent – 1.5 times the landmass of India.

Behind concrete’s image problem are its emissions. Responsible for 7-8 percent of humanity’s greenhouse gas output, the industry’s carbon footprint is larger than that of all but two countries – four times that of aviation. Given this massive scale, even small emissions reductions can have a large effect.

Concrete’s essential role in development

Concrete has become a vital enabler of development. It is versatile, easy to work with, and immensely popular. As individuals escape poverty, they dream of living within solid concrete walls. And without concrete, it would be impossible to build highways, bridges, airports, shopping malls, and other essential infrastructure.

Fortunately, Heierli says there are ways to curb emissions. Low-carbon cement formulations like LC3, paired with efficiency gains in cement production and concrete construction, could mitigate up to 70 percent of the sector’s emissions, without resorting to carbon capture and storage technologies (CCS) that are still too costly for the Global South.

Housing a small piece of the bigger picture

“When we began, we expected efforts to meet housing demand in the Global South to have a massive carbon footprint. Our first big eye opener was that basic housing, even at such a large scale, doesn’t require that much cement,” says co-author Anthony Boanada-Fuchs.

Because basic housing required to meet demographic demand, upgrade slum dwellings, and renew old structures only uses around 3.5 tons of cement – a fraction of the 27 tons needed to meet European space standards – its global warming impact is modest. With LC3 cement, the required 40 million housing units per year could be built with a carbon footprint of around 0.3-12.5 percent of each country’s emissions. “The main factor driving concrete use in housing is area consumption per person. This opens a new set of questions around housing standards and spatial justice,” he says.

Demand for cement far exceeds development metrics

Concrete is often associated with the Global North. But demand has long moved elsewhere. Today, 94 percent is produced in the Global South, with important strategic consequences for addressing climate change, says Scrivener: “People think we can solve the industry’s problems in the Global North but don’t realize that cement makes up 1.5 percent of carbon emissions in the US and three percent in Europe. In the Global South, it’s 20 percent.”

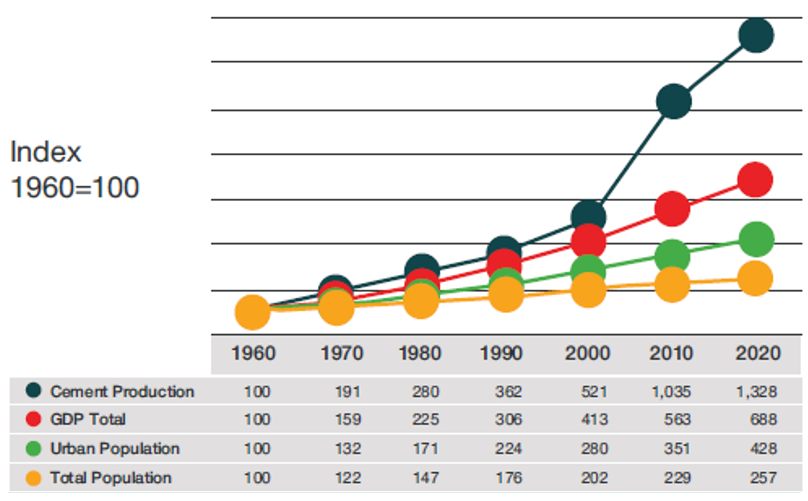

As countries see their populations grow, GDP increase, and societies urbanize, demand for concrete rises. Of the three self-reinforcing factors, urbanization and all the infrastructure that it requires is the most important driver. But as the world population grew 2.5-fold, urban populations 4.3-fold, and global GDP 7-fold from 1960 to 2020, cement production was multiplied by 13. Thirty years of spectacular development saw China’s cement production surge to more than half of global production today.

Anticipating rising demand in Asia and Africa

The next bubble is already in the making – in Africa. “Africa may not urbanize exactly the same way as China. But what’s clear is that cities there can only grow in one direction: upwards. With other materials you can’t build a second or third floor as effortlessly as with cement,” says Heierli.

The report warns that without urgent measures to decarbonize the cement sector, this surge in demand could result in 95 billion tons of emissions; almost a quarter of the remaining carbon budget to keep warming below the Paris Agreement’s 1.5 °C limit.

“Now we need to act in Africa before the infrastructure gets built,” says Scrivener. She sees rapid adoption of LC3 as an effective means of mitigating these emissions without the cost of other technologies, such as carbon capture and storage.

LC3: A potential game changer for the Global South

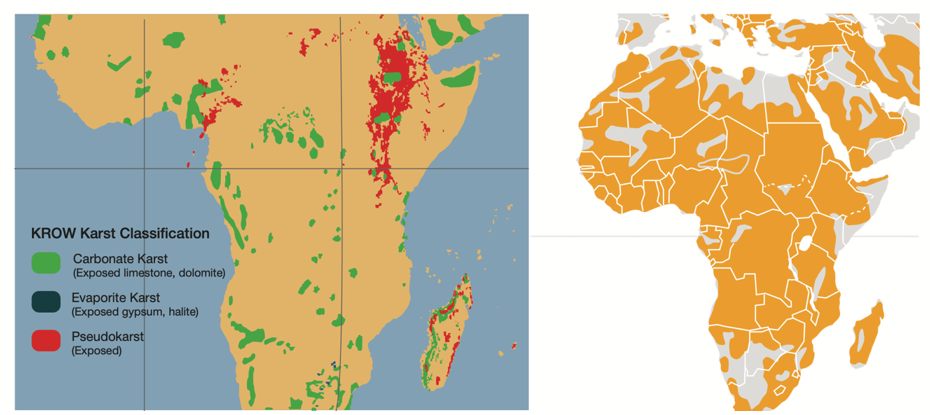

According to the report, LC3 offers a viable alternative to standard cement, particularly in Africa. “Unlike limestone, which is scarce across Africa, the low-grade clay used in LC3 cement is available almost everywhere,” says Heierli. This paves the way for local low-carbon cement production.

LC3 could also unleash Africa’s construction sector. “Construction is a job engine that can employ millions of young people. Producing LC3 locally could generate jobs and control the cost of concrete. And because LC3 behaves like standard cement, with similar or superior performance, workers don’t need training in its use,” says Heierli.

Going forward, the most important challenge is encouraging countries to update construction standards to include LC3 – a prerequisite for its adoption. “In the near term, we need to put in place partnerships with these countries, educate professionals and policymakers, and create and strengthen research capacities in the South. This is where things have to go next,” he says.

29 May 2024, by Jan Overney

Photo credit courtesy of © 2021 Cementos Argos